Certified devices according to the EN 12830 standard offer various advantages to users and device manufacturers.

- Quality Assurance: Certification according to EN 12830 ensures that devices meet the strict technical specifications outlined by the standard, ensuring the quality of measurements.

- Measurement Accuracy: Certified devices are designed to provide high accuracy in temperature measurements.

- Compliance with Safety Standards: Certification ensures that devices comply with safety standards, protecting both users and the environment from potential hazards.

- Operational Reliability: Certified devices are designed to operate reliably in various conditions, ensuring stable and accurate measurements.

- Compatibility with Other Systems: Certified devices are usually compatible with other measurement and data management systems.

- Compliance with Legal Requirements: The use of certified devices complies with legal requirements and regulations for temperature measurements.

EN 12830 Standard Requirements for Refrigerators and Freezers

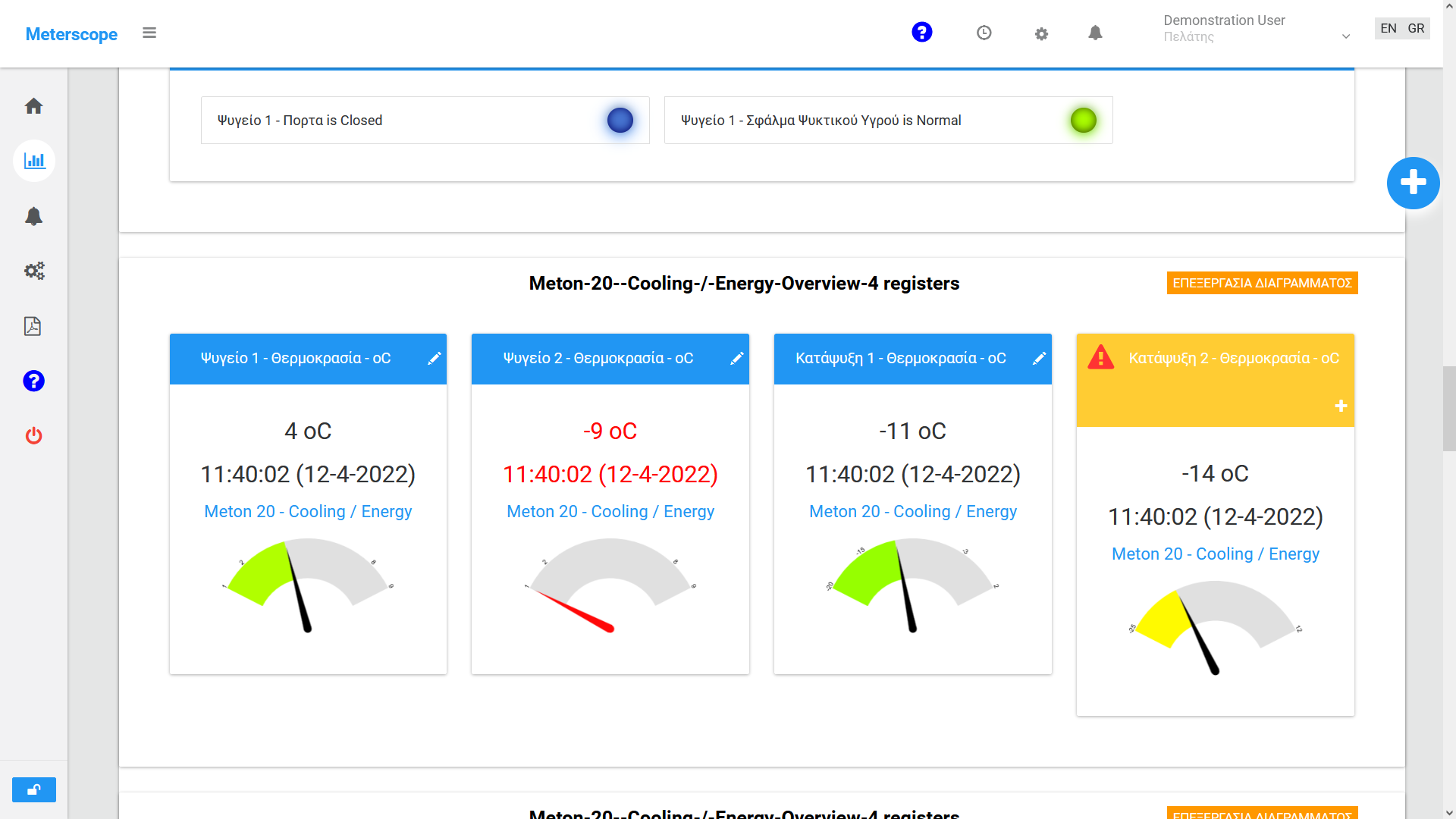

Measurement Accuracy

- Temperature: ±0.5°C across at least the -25...+7°C temperature range (EN 12830:2018, 5.10.2.2)

Measurement Frequency

- Specifies the measurement frequency for temperature.

- Selected to cover hazardous conditions yet flexible enough to meet application requirements without unnecessary measurements.

These requirements ensure not only accuracy but also the appropriate frequency of measurements to meet the needs of the application without unnecessary burden on the system.

Data Management

- Data Storage: Data resulting from measurements must be stored for an appropriate period.

- Data Retrieval: The standard allows for the retrieval of stored data, crucial for verification, analysis, and utilization of measurements.

- Controlled Access: The standard may specify measures for controlled access to data to protect against unauthorized access.

- Reports and Documents: Preparation of reports and documents related to measurements, data, and operating conditions is required for transparency and reliability.

-

Malfunction Detection: Detecting malfunctions is crucial for immediate response to potential issues, protecting refrigeration equipment, and maintaining suitable conditions. Needs for anomaly detection may include:

- Alarms and Notifications: Installation of alarm mechanisms and notifications in case of irregularities or exceeding temperature limits.

- Automatic Recording of Malfunctions and Events: A system for the automatic recording of events to be available for future analysis.

- Data Analysis: Applying data analysis methods to identify proposed patterns and anomalies in measurements.

- Functionality Tests: Procedures for checking and testing functionality to ensure the proper operation of measurement systems.

Conclusion